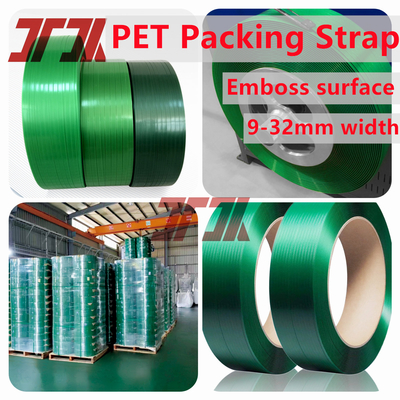

Kunststoffmaschinen Hochgeschwindigkeitsmaschine zur Herstellung von PET-Gürteln

Produktbeschreibung

ExtrusionsschirmeDer Extruder derProduktionslinie für Stahlgürtel aus PET-KunststoffDie Schraube verfügt über eine einzigartige Trenn- und Mischwirkung, die eine gleichmäßige Plastifizierung der Rohstoffe gewährleistet.Es hat die Vorteile eines großen Extrusionsvolumens, gute Weichmachung, hohe Härte und hohe Verschleißfestigkeit.

Filter --Drei-dimensionale faltbare Großflächenfiltervorrichtung, die entfaltete Fläche des Filters ist 30-mal größer als die der herkömmlichen flachen Filterfläche; das Filternetz kann 80 Maschen erreichen,und die einzigartige Bildschirmwechselvorrichtung reduziert die Bildschirmwechselzeit erheblich und verbessert die Arbeitseffizienz.

Dehumidifikator------ Das Dreh- und Trocknungssystem aus Honigstock wird zur Trocknung der Rohstoffe verwendet.und hat auch die Wirkung von Festphasen-Polycondensation und Viskositätserhöhung.

Produktbeschreibung

| Modell |

PET-2 |

PET-3 |

PET-4 |

PET-6 |

PET-8 |

| Rohstoffe |

Flaschenflocken/zerkleinerte Stoffe |

| Anzahl der Bänder |

2 |

3 |

4 |

6 |

8 |

| Breite (mm) |

9 bis 32 |

| Stärke (mm) |

0.4-1.2 |

| Höchstgeschwindigkeit der Leitung ((m/min) |

₹ 150 |

₹ 150 |

₹ 150 |

₹ 150 |

₹ 150 |

| Schraubmodell |

90 |

100 |

125 |

150 |

180 |

| Modell der Reduktoren |

200 |

250 |

280 |

315 |

350 |

| Entfeuchter |

1000 |

1000 |

2000 |

3000 |

3500 |

| Zählerpumpen |

100CC |

| Produktionskapazität /24 h |

5 bis 6T |

7-8T |

10-12T |

12-15T |

18-20T |

Merkmale von Kunststoffbanden

Die wichtigsten Funktionen von PET-Härten:

Verbesserung der Stoßbeständigkeit --- Durch die Steigerung der Zähigkeit von PET wird die spröde Bruchbarkeit beim Stoß reduziert.

Verbesserung der Verarbeitungsleistung ---- Verringerung der Verarbeitungstemperatur, Verringerung des Energieverbrauchs und Verbesserung der Flüssigkeit, um die Verarbeitung reibungsloser zu gestalten.

Verbesserung der Flexibilität-------Make PET-Materialien weicher und geeignet für Anwendungsszenarien, die Flexibilität erfordern.

Verbessern Sie die Wärmebeständigkeit------- Einige Härtemittel können die Wärmebeständigkeit von PET verbessern, so dass es bei hohen Temperaturen eine stabile Leistung aufweist.

Dienstleistungen nach dem Verkauf

Wir haben ein erfahrenes technisches Team, das schnell eine Vielzahl von Dienstleistungen erbringen kann, darunter:

Vorverkauf:

1. Layout von PET-Plastik-Stahlgurtgeräten.

2Analyse der Fertigungskosten von PET-Plastik-Stahlgurtgeräten.

3Analyse der Rohstoffe, die in der PET-Plastik-Stahlgurtanlage verwendet werden.

Dienstleistungen nach dem Verkauf:

1. Wasserstraßenschema, Stromkreisdiagramm, Rohrleitungsverbindungszeichnungen usw. von PET-Plastik-Stahlgurtgeräten.

2Installation, Inbetriebnahme und Ausbildung von PET-Plastik-Stahlgurtgeräten.

3- Wartungsdienst für PET-Plastik-Stahlgurtgeräte.

4Regelmäßige Wartung und Reparatur

5. Fehldiagnosen

6. Software-Aktualisierung und -Upgrade

7Ersatzteile und Zubehör

8- Ausbildung und technische Beratung

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!  Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!

Gesamtbewertung

Rating-Schnappschuss

Die folgende Verteilung zeigt alle Bewertungen.Alle Bewertungen